How do you prepare structural steel before applying intumescent paint?

Preparing structural steel before applying intumescent paint is crucial to ensure the paint adheres properly and provides the necessary fire protection. Here are the steps involved in preparing structural steel for intumescent paint application.

If the steel is new and you know the exact primer which is on your steel, please submit the technical / product data sheet to our technical team on sales@fireproofpaint.co.uk for a compatibility check.

If the primer is compatible and in tact then go to 2: Degreasing.

If the Primer is unknown, in poor condition, or not compatible go to 1: Surface cleaning

1 – Surface Cleaning

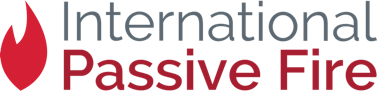

Remove all dirt, dust, rust, and contaminants from the steel surface. This can be done using wire brushes, abrasive pads, paint stripping or sandblasting, depending on the severity of the surface condition.

Modern steel should be blast cleaned before application of the primer at the steel fabricators. If the steel has not been blast cleaned we would not recommend the use of intumescent paints.

The cleaning grades possible to obtain are:

St 2: Thorough hand and power tool cleaning

St 3. Very thorough hand and power tool cleaning

These cleaning grades are used if the steel has a blast profile. These grades are all from ISO 8501:2007

The preparation grades for blast cleaning are:

- Sa 1: Light blast cleaning

- Sa 2: Thorough blast cleaning

- Sa 2½: Very thorough blast cleaning

- Sa 3: Blasting to visual clean metal

A preparation standard of Sa 2½ is used if the steel does not have a blast profile. These grades are all from ISO 8501-1:2007.

2 – Degreasing

Ensure that the steel surface is free from oils, grease, and other contaminants. Use a suitable degreasing solvent or detergent to clean the surface thoroughly. Ensure that the solvent cleaner does not affect the primer before use.

3 – Primer Application

Depending on the specific intumescent paint system and steel condition, you need to apply a compatible primer. Primers are required and are part of the fire protection system when using intumescent paints.

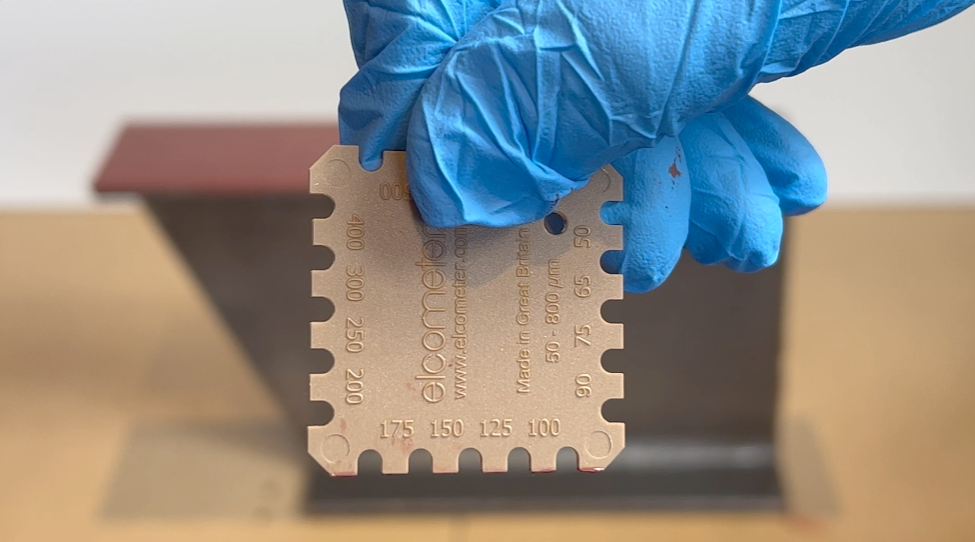

Each primer has a recommended dry film thickness (DFT) to ensure that the steel is protected. The DFT is set down by the manufactures, for example “Primer A” can be applied at a DFT between 75 and 150 microns. When the primer is applied at the required DFT the intumescent system will perform correctly.

4 – Surface Inspection

After cleaning, rust removal, and primer application, inspect the steel surface to ensure it meets the required cleanliness, roughness and complete coverage of the primer. We recommend doing a DFT primer check to ensure the primer is applied at the correct thickness. You can carry out this DFT check by using a DFT gauge, such as the ones we supply on our website.

Any imperfections should be corrected before proceeding.

Once the inspection has been completed and you are satisfied with the above then you can proceed to apply the intumescent paint.

It’s crucial to follow the manufacturer’s guidelines and consult with a professional experienced in primer / intumescent coatings to ensure that the process is carried out correctly and that the steel receives the necessary fire protection. Additionally, local building codes and regulations may specify certain requirements for intumescent paint application on structural steel, so always check for compliance with these standards.